Plastic Injection Mold (Large size) Overlay Repair

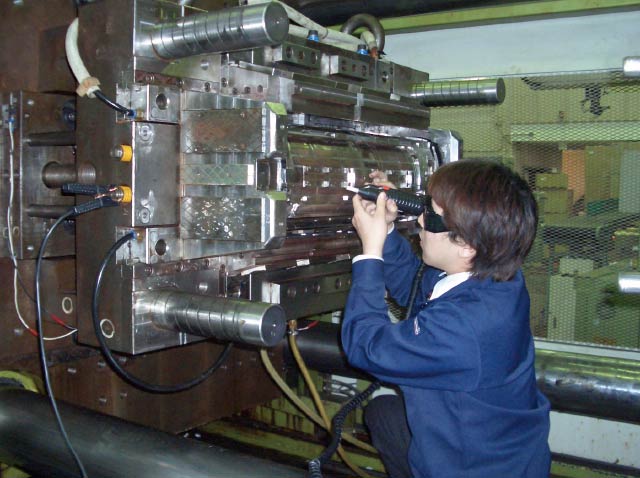

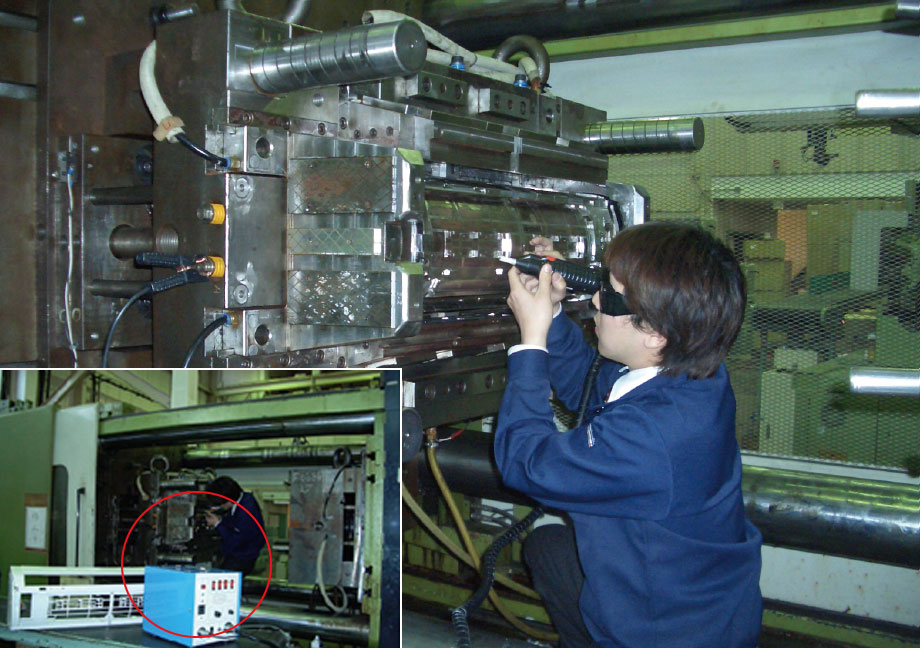

Overlay Repair is possible only to necessary part without dis-mantle from injection machine

Total mold weight has 10 tons, and took longer time to dis-mantle from injection machine and re-setting.

And, the dimensional accuracy difference occurred when Overlay Repair and Precision Finishing are done after mold temperature is dropped to room temperature, and the size when the mold is set to the molding temperature after Repair and the mold temperature is raised to the molding temperature.

There is a slight difference in the heat shrinkage / expansion of the mold in terms of accuracy, and burr is occurred again.

Depo series Improvement Examples

| Work | Room Air Conditioner Case Mold |

|---|---|

| Total Weight | 10 tons |

1. No much extra Overlay amount and no machining finishing required

Allow to do Overlay Repair in any position with little excess Overlay amount.

Possible to do hand finishing by grinders, files, or oil stones without machining finish required.

Possible to do hand finishing by grinders, files, or oil stones without machining finish required.

2. Possible Overlay Repairing molds without dis-mantle from injection machines

The Device is portable and processable with household power supply.

Possible to do Overlay Repair mantled mold in injection machine without cool down the temperature.

Possible to do Overlay Repair mantled mold in injection machine without cool down the temperature.

3. Greatly improved work efficiency

Molds temperature is not down to be able to do a trial molding and may confirm availability of burr occurring and repaired condition easily.

Related Product

Coating and Overlay Device

Depo Series〈Depo〉

Best Solution for Preventive Maintenance and Over Repairing of Machine Parts, Mold and Dies

Depo Series are a newer Coating and Overlay method applying EDM (Electrical Discharge Machining) principle.

Depo Series are a newer Coating and Overlay method applying EDM (Electrical Discharge Machining) principle.