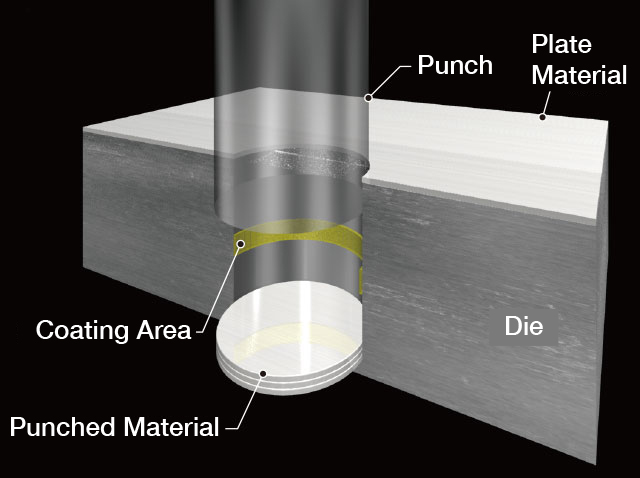

Scum Riser Prevention for Press Die

Coating on Die / Punch improves Wear and Heat Resistance

Tungsten Carbide (WC) proceeds and equips Wear and Seizing Resistance on Die and Punch, and may prevent punching plate material lifting and adsorption.

Especially effective for sticky materials like Stainless Steel and Aluminum.

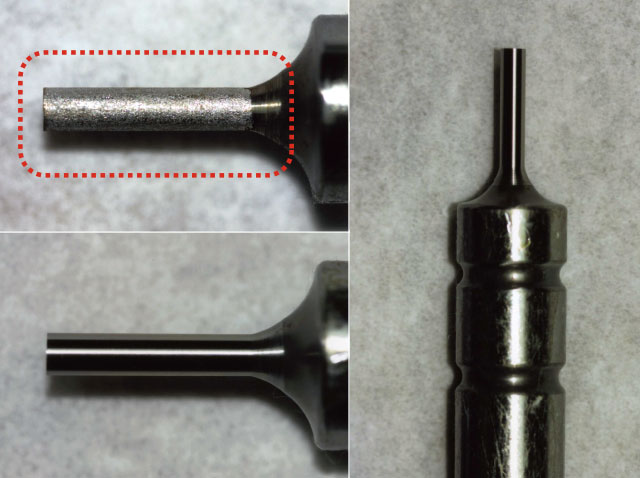

Die / Punch Coating Example

-

Coating on Punch 1

-

Coating on Punch 2

Scum Rising Cause and Problem on Pressing Process

| 1 | Vacuum Adsorption |

|---|---|

| 2 | Cutter Adsorption by Punched Material etc. |

| 3 | Oil Film Adsorption |

| 4 | Magnetic Force Adsorption by Punch (Remanence) |

| 5 | Push up Die by Compressed Air |

For these causes, there are some countermeasure that punch processing, equip air-holes (air blow), adding ejector pins, adjusting entry amount of punching, and modify punches to all taper.

However, we can not ignore costs and time of punches and dies replacement, design modification, or equipment procurement.

However, we can not ignore costs and time of punches and dies replacement, design modification, or equipment procurement.

Related Product

Coating and Overlay Device

Depo Series〈Depo〉

Best Solution for Preventive Maintenance and Over Repairing of Machine Parts, Mold and Dies

Depo Series are a newer Coating and Overlay method applying EDM (Electrical Discharge Machining) principle.

Depo Series are a newer Coating and Overlay method applying EDM (Electrical Discharge Machining) principle.