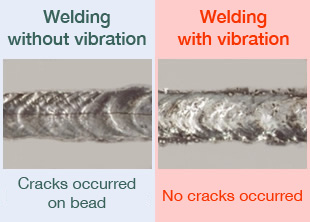

Strengthened by vibration during welding, preventing distortion and cracks

Finer metal particles improve welding strength

Prevents distortion and cracks

The argon, arc, gas or plasma welding.

Vibration applied during welding and cooling time makes crystal grain size smaller and improves the characteristics of welded portions and the vicinities, preventing internal warp and cracks and enhancing fatigue resistively.

It is a byproduct that welding is realized with less electric power if done together with vibration, consequently less preheat energy is needed and a subsequent cooling time is shortened.

Effect of vibration during welding

-

TIG welding while vibrating the mold

-

Effect of vibration during welding

Example of strain / crack prevention by vibration during welding

| Type | Part name | Weight (kg) | Material | Purpose / Effect |

|---|---|---|---|---|

| Repair Welding | Forging Machine Ram | 5,000 | SC | Execute during Ram’s cracking repairing from starting to the period (cooling) to prevent distortion and under-cut with reducing pre-heating and post-heating temperature. |

| Automobile Mfg. | Automotive Outer Panel Press Die | 3,000 | FCD | Processing tolerance improvement, man-hours reducing, before and after overlay welding, and distortion prevention after operation. |

| Automobile Mfg. | Tank Frame | 10,000 | SS | Execute during welding assembly to improve accuracy. |

| Industrial Machinery Mfg. | Steel Plate Column | 7,000 | SS | Execute processing during welding to improve weldability and accuracy. |

| Construction Machine Repair | Bucket | 1,000 | Mn Alloy | Execute processing at joint and overlay welding to prevent distortion and cracking. |

| Shipbuilding | Bucket | – | Al | Execute during Al welding to improve weldability and to prevent distortion. |

Many other applications might be considered. Please contact us about your problem.

Related Product

Coating and Overlay Device

VibroDyn

VibroDyn is an equipment to alleviate or remove internal stress in metals using vibrational energy

The resonance waveform can be visualized by a simple operation, and the natural resonance point of the workpiece can be detected and easily processed with vibration effective for stress reduction.